Pad printing is the best method of converting a 2D image into a 3D model. It is largely regarded as the most popular method of promotional branding, over modern digital printing, due to its adaptability to be printed on unconventional, uneven or obscure surfaces. Its versatile applicability, cost-effective price and detailed and colourful touch, make pad printing the optimal form of promoting your brand or logo.

What is Promotional Pad Printing?

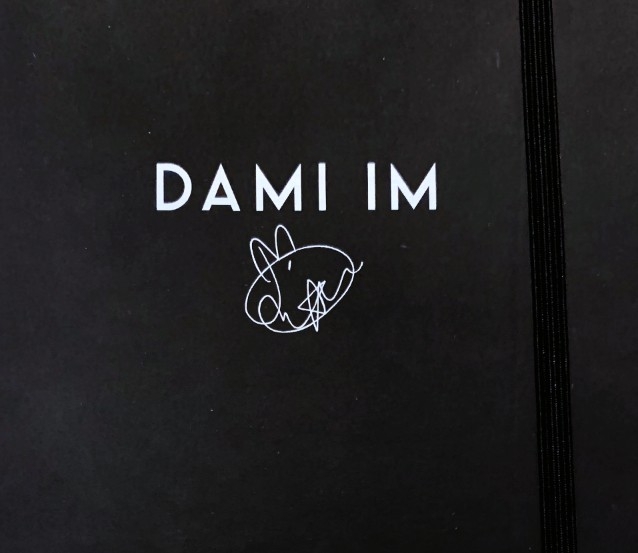

Promotional Pad Printing is the process of decorating a product with your company’s unique brand or logo. This is achieved by transferring a colour of ink onto a promotional product of your choosing. Pad Printing is perfect for bulk products, which makes it ideal for items such as branded notebooks, stress balls, reusable coffee cups, stationery, tools and equipment and much more! You may like to think of promotional pad printing as using an old school rubber stamp, dipping it in ink and stamping your products to print your image.

How is Pad Printing Achieved?

Pad Printing begins with us obtaining a high-resolution image of your brand or logo as an AI, EPS, or vectorised PDF format. Then, we will ask you to select the colour of the ink. Not only do our ink choices vary but certain inks that contain additives ensure the best performance on plastics, while inks with hardeners are mostly used for ceramics and glassware.

Next, we take an embossed stereoplate (which is just a solid plate of some sort of metal) and coat it with the colour of ink of your choosing. We wipe off excess ink so that just your logo or brand remains. With your confirmation, we use a silicone pad to transfer this image onto the promotional item you want to be printed.

Decoration Using Pad Printing

A Pad Printing machine will hold both the pad and the product and repeatedly press the pad into an ink plate, which has been customised to suit the design of your brand or logo. With this technology, the silicone pad adjusts itself to the shape of the product without distorting the quality of your image. Once pressed onto the object it is left to air dry. It is as simple as that!

You should note that the content of the silicon will determine the hardness of the pad. Usually, a softer pad will be used on a more uneven and obscure surface. Also, the ink will be formulated to match the type of material it is to be printed on so take care in thinking about the type of promotional product you wish to have your brand on. Additionally, if you wish to coat your promotional product with a film or glossy cover, we will need to administer special treatment (before or after) we begin printing. This typically involves flaming or baking the products to ensure it takes to the slippery surface.

Why Use Pad Printing

Due to its variability, cost-effectiveness, easy maintenance and durability, pad printing is the perfect way to promote your company’s brand or logo on a unique product. Having the ability to reproduce your image on a 3D surface in any shape or size makes it something that you cannot pass up.